OEM 316L Stainless Steel Pin Watch Buckle Mirror Buffing Finish

Basic Info

| Model NO. | SFSCON001 |

| Display Methods | Analog |

| Style | Fashion |

| Size | Customized |

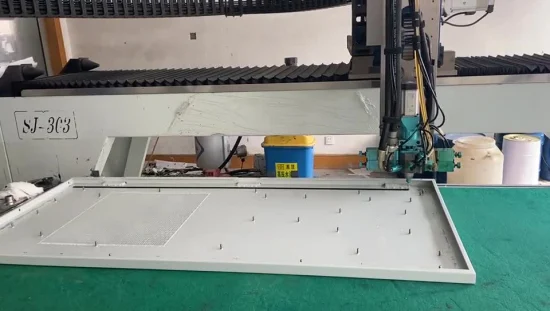

| Forming Method | Powder Injection Molding |

| Mold Material | Per Request |

| Transport Package | Air Freight/Ocean Freight /Per Request |

| Specification | Customised |

| Trademark | OEM |

| Origin | China |

| HS Code | 8517703000 |

| Production Capacity | 1000000 Piece Per Month |

Product Description

OEM 316L Stainless Steel Pin Watch Buckle Mirror Buffing Finish

SFS metal Products experienced at producing MIM part for today's Mobile phone components. We specialize in metal injection molding of soft magnetic alloys, stainless steel, and a range of other ferrous metals. The MIM process is ideal for producing small, complex electrical components with excellent mechanical properties.

SFS MIM also carry experience in assisting customers in design for manufacturability for their MIM components across many areas of the defense industry, which includes:

Fiber Optic Connectors, Filter Components, Heat Sinks, Microwave Equipment, Mobile Phones, Solenoids, Micro-Switches, Standoffs, Connectors, Distribution Frames, Switching Components, Connectors, heat sinks, Armatures, housings, injector nozzles, Buttons, cosmetic products, handles, levers, seating mechanisms, Braking & ABS components, seat belt mechanisms, Sensor housings, triggers, fire suppression, magazine catch, cam block and rear rail.

MIM easily produces parts with complex shapes, superior strength, and excellent surface finish. Our MIM manufacturing experts will make your precision parts fast.SFS MIM Products has extensive industry expertise. This includes complete process engineering, designing and implementing automation, quality assurance, assembly, packaging and product fulfillment and distribution.

Send us your CAD File or Drawings and we'll give you an appraisal of the viability of MIM molding for your new or existing project.

WHY US ?1. We are a professional manufacturer specializing in manufacturing various metal parts, including CNC precision turning parts, CNC precision milling parts, automatic lathe parts, EDM wire cutting parts etc for over 10 years.

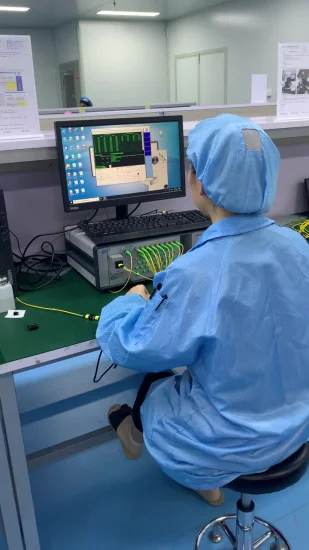

2. With experienced technical engineers and modern inspection equipment, our factory can help you to lower cost at the moment of worldwide financial crisis.

3. We are committed to focusing on the client's demand and satisfaction, and to providing high quality products at competitive prices according to your drawings or samples. Special parts for your special needs!

4. Our strong R&D and QC department can control the products to meet your strict requirment, 100% inspection on critical dimensions with high accuracy +/-0.005mm.

5. Factory direct price and on time delivery.

6. Small quantity acceptable.

7. Free samples available.

8. OEM workable.

F .A.Q

1. Are you a factory or a trading company?

A: We are a factory which has been specialized in metal injection molding of soft magnetic alloys, stainless steel, and a range of other ferrous metals.

2. Where is your factory and how can I visit it?

A: Our factory is located in Shenzhen city .30 minutes away by car from airport and seaport.

- How long can I get some samples for checking and what about the price?

A: Normally samples will be done within 3-4days .The sample cost depends on all information (size, material, finish, etc.). We will return the sample cost if your order quantity meets MOQ.

4. How is the warranty of the products quality control?

A: We hold the tightend quality controlling from very beginning to the end and aim at 100% error free.

5.How to get an accurate quotation?

A: If you are interested in our products, please provide us with below information:

♦ Drawings, photos or samples of products.

♦ Detailed sizes of products.

♦ Material of products.

♦ Surface treatment of products.

♦ Ordinary purchasing quantity.